Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Product Application:

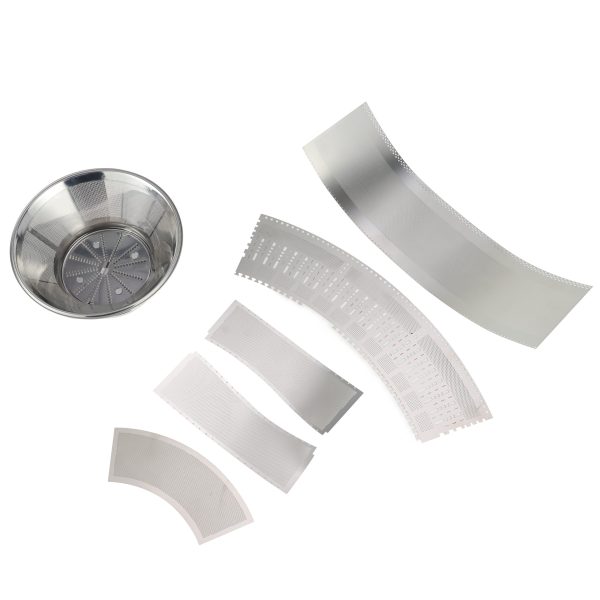

Primarily utilized in vacuum cleaners, hair dryers, automotive lubricants, electrical appliances, hardware components, kitchen oil pans, kettles, and other products to serve a critical filtering function.

| Product Name | Stainless Steel Etching Filter Mesh | Product Classification | Filtration Product Accessories |

| Item Model Number | KC972410013 | Appearance | Mirror Finish/satin finish/Brush Finish |

| Origin | Guangdong China | Colour | Silver |

| Material | SUS304 | Processing Technology | Stamping, stretching and Etched |

| MOQ | 500 units.

The specific requirements will be determined based on the specifications and manufacturing processes of the products as dictated by the customer. |

||

| Delivery Cycle | For orders of up to 500 sets, the estimated delivery time is approximately one month. However, the production processes and corresponding delivery times may vary depending on the specific materials, styles, and specifications of the products. | ||

Product Description

Stainless Steel Etching Filter Mesh – The go-to hero for all your filtration needs!

Looking for a dependable filter? Stainless Steel Etching Filter Mesh is the way to go. It’s used in everything from vacuum cleaners and hair dryers to automotive oil systems, electrical appliances, hardware, and even kitchen items like oil pots and kettles. This mesh offers top-notch protection against corrosion and wear, making it perfect for tough environments with acids or alkalis. Plus, it can handle temperatures up to about 480°C and stands up well under pressure.

The best part? It’s super easy to work with—whether you need to cut, bend, stretch, or weld it—and cleaning is a breeze, especially with backwashing. The surface is smooth and flawless, no burrs or weird holes, which not only looks great but also helps it last longer. And if you need something custom, we’ve got you covered. We can tailor the size and specs to fit your exact needs. Ready to give it a try? You’ll love the quality and performance!

Product Features:

1. Corrosion and Wear Resistance: Stainless steel inherently possesses superior corrosion and wear resistance, enabling prolonged use in harsh environments such as acidic and alkaline conditions without degradation.

Reviews

There are no reviews yet.